New Construction Helical Pier System, Foundation Under Pinning

South Dakota | Nebraska | Wyoming

Helical piles consist of a steel central shaft with one or more helical shaped bearing plates that are sometimes referred to as blades or flights and are welded to the lead section. Extension shafts are used, with or without blades, to extend the unit down into the earth until they reach the proper depth for load-bearing and capacity. Brackets at the tops of the piles are used to attach the pile to a structure, whether new or in a retrofit application.

Helical piles consist of a steel central shaft with one or more helical shaped bearing plates that are sometimes referred to as blades or flights and are welded to the lead section. Extension shafts are used, with or without blades, to extend the unit down into the earth until they reach the proper depth for load-bearing and capacity. Brackets at the tops of the piles are used to attach the pile to a structure, whether new or in a retrofit application.

Helical piles, screw piles, helical piers, helical anchors, helix piers and anchors are all used interchangeably by most people though the term pier usually refers to a helical pile loaded in axial compression while the term anchor usually refers to a helical pile loaded in axial tension.

Design Considerations

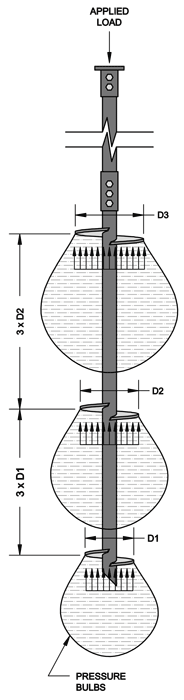

Helical piles are designed such that most of the axial capacity of the pile is generated through bearing of the helix blades against the soil. The helix blades are typically spaced three diameters apart along the pile shaft to prevent one blade from contributing significant stress to the bearing soil of the adjacent blade. Significant stress influence is limited to a ‘bulb’ of soil within about two helix diameters from the bearing surface in the axial direction and one helix diameter from the center of the pile shaft in the lateral direction. Each helix blade therefore acts independently in bearing along the pile shaft.

Helical piles are designed such that most of the axial capacity of the pile is generated through bearing of the helix blades against the soil. The helix blades are typically spaced three diameters apart along the pile shaft to prevent one blade from contributing significant stress to the bearing soil of the adjacent blade. Significant stress influence is limited to a ‘bulb’ of soil within about two helix diameters from the bearing surface in the axial direction and one helix diameter from the center of the pile shaft in the lateral direction. Each helix blade therefore acts independently in bearing along the pile shaft.

Multiple piles shall have a center to center spacing at the helix depth of at least four (4) times the diameter of the largest helix blade (ICC-ES AC358). The tops of the piles may be closer at the ground surface but installed at a batter away from each other in order to meet the spacing criteria at the helix depth. For tension applications, the uppermost helix blade shall be installed to a depth of at least twelve (12) diameters below the ground surface (ICC-ES AC358).

SupportworksTM Model 287 Helical Pile System

Model 287

SupportworksTM Model 287 Helical Pile System

Technical Specifications

|

Bracket Specifications

|

Model 288

SupportworksTM Model 288 Helical Pile System

Technical Specifications

|

Bracket Specifications

|

View our product brochure and product specifications documents.

Model 350

SupportworksTM Model 350 Helical Pile System

Technical Specifications

|

Bracket Specifications

|

Determination of Capacity

The ultimate capacity of a helical pile may be calculated using the traditional bearing capacity equation:

The ultimate capacity of a helical pile may be calculated using the traditional bearing capacity equation:

Qu = ∑ [Ah (cNc + qNq)]

| Where: |

|

Total stress parameters should be used for short-term and transient load applications and effective stress parameters should be used for long-term, permanent load applications. A factor of safety of 2 is typically used to determine the allowable soil bearing capacity, especially if torque is monitored during the helical pile installation.

Like other deep foundation alternatives, there are many factors to be considered in designing a helical pile foundation. SupportworksTM recommends that helical pile design be completed by an experienced geotechnical engineer or other qualified professional.

Another well-documented and accepted method for estimating helical pile capacity is by correlation to installation torque. In simple terms, the torsional resistance generated during helical pile installation is a measure of soil shear strength and can be related to the bearing capacity of the pile.

Qu = KT

| Where: |

|

The capacity to torque ratio is not a constant and varies with soil conditions and the size of the pile shaft. Load testing using the proposed helical pile and helix blade configuration is the best way to determine project specific K-values. However, ICC-ES AC358 provides default K-values for varying pile shaft diameters, which may be used conservatively for most soil conditions. The default value for the Model 288 Helical Pile System (2 7/8-inch diameter) is K = 9 ft-1.